UN (max. density: 1.9)

TOPline

Intermediate Bulk Container

TOPline IBC

Versions & accessories

TOPline IBCs are tested and approved for filling with hazardous liquids according to UN 31 HA1/Y/D/BAM. The UN marking is applied to the inner container and the label plate.

- Approved up to a density of max. 1.9

- Available in all volumes

- Particularly robust inner container (PE new goods)

Dimensions

The following dimensions are standardised IBCs for filling materials up to a density of 1.6 Rho

Volumes | length | width | height |

|---|---|---|---|

300 | 600 | 800 | 1000 |

600 | 1200 | 800 | 1013 |

800 Euro | 1200 | 800 | 1078 |

800 | 1200 | 1000 | 1000 |

1000 | 1200 | 1000 | 1163 |

Valves

We offer integrated or replaceable valves.

Volumes | DN 50 mm | DN 80 mm |

|---|---|---|

300 | ||

600 | ||

800 | ||

800 Euro | ||

1000 |

Lid

Volumes | DN 150 mm | DN 225 mm |

|---|---|---|

300 | ||

600 | ||

800 | ||

800 Euro | ||

1000 |

The plus in service

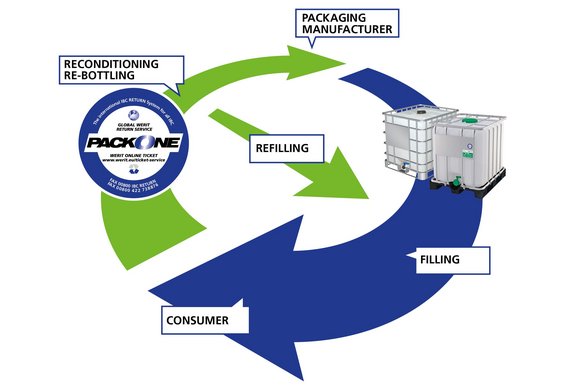

WERIT offers their customers a high level of service - these include the IBC reconditioning, return of containers free of charge and the collection of used and emptied IBCs.

When handling raw materials and resources in a responsible manner, WERIT works continuously on new innovative and intelligent solutions for packaging systems, their collection and environmentally-friendly recycling. The WERIT IBC module system plays off its strengths to the fullest here: it permits a trouble-free cleaning as well as an ecological reconditioning by the replacement of individual components. In this way, WERIT guarantees the resource-conserving and economical multi-way usage.

Via the WERIT RECOline, we take back all WERIT IBCs and return them to the resources cycle. You are looking for a competent partner for the return of emptied IBCs of other manufacturers? This is guaranteed to you via PACKONE©. A special inner container designed by WERIT permits, independent of the brand, the reuse of the IBC module so that a UN approved PACKONE-IBC is generated as good as new.

Use our All-in-One PackOne WERIT Ticket service today and get us to collect your used and emptied container free of charge (please note our collection conditions). Simply fill in the IBC return ticket - we will take care of the rest.

FAQ

Frequently Asked Questions

HDPE is a robust and durable plastic which, in case of our IBC containers, is translucent and protects the content against UV radiation. Our IBC accessories also comprise this special material. HDPE is generated by the industrial polymerisation of ethane. At the beginning, this raw material was milky and waxy. However, today it has developed to an innovative thermoplastic plastic with ideal deformation properties and can be adjusted optimally to all specific requirements by the addition of additives. The HDPE that we use is dimensionally stable at temperatures from -40 to +70 °C and resistant against most alkalis, acids and chemicals.

An interesting fact at the end: HDPE has already been used commercially since 1957 for cable insulation, piping systems and packaging material.

The dimension for the filling opening is the same for all three product lines. The ECOline IBC (non UN), TOPline IBC (UN) as well as the POLYex IBC containers are equipped either with an NW 150 or NW 225 filling opening with screw lid and an optional venting. The ECOline IBC (non UN) is additionally available with an NW 400 filling opening with clamping ring lid.

All of our IBC containers are equipped with a NW 50 or NW 80 discharge valve which is integrated or replaceable.

Naturally. Our containers are suitable for almost all liquids - why shouldn't it also be used as a rain tank? The (food product) industry is already also using water tanks today.

The WERIT IBC is particularly suitable for reuse and reconditioning due to its robust construction and durability. The company has developed a unique take-back and circular system for all used IBC containers, regardless of manufacturer or design.

WERIT offers the free return of all IBC containers through the PACKONE ticket service. Reliable partners handle the collection of used IBCs and their professional reconditioning. After cleaning the IBC or replacing the inner container, the IBCs are prepared for refilling – promoting a resource-efficient approach to raw materials and environmental sustainability.

Modern logistics processes across various industries, such as chemicals, automotive, and pharmaceuticals, demand sustainable and resource-efficient processes as well as circular systems. Strong partnerships provide a solid foundation for ensuring perfect and safe performance. Due to its robust design and durability, the WERIT IBC is particularly well suited for reuse and reconditioning.

The company has developed a unique take-back and circular system for all used IBCs, regardless of manufacturer or model. For your convenience, WERIT offers the free return of all IBC containers through the PACKONE ticket system. Reliable partners manage the collection of used IBCs and their professional reconditioning. After cleaning or replacing the inner container, these IBCs are returned to the economic cycle, promoting the sustainable use of raw materials and environmental protection.

Many customers have recognised the significant logistical and economic advantages and now use WERIT’s Open- or Closed-Loop system. By reconditioning returned Intermediate Bulk Containers, this type of packaging serves as a model for environmentally friendly transport and bulk packaging. After cleaning or replacing the inner container or individual components, these IBCs are reintegrated into the supply chain. The functionality and usability of reconditioned IBCs, including UN-certified models, are nearly equivalent to new products.

Both cleaned and rebottled IBCs undergo the required inspections and tests to ensure that reconditioned UN-certified IBCs are safe for transporting hazardous materials.

With WERIT’s various circular systems, including Closed Loop and Open Loop, we can respond optimally to customer-specific requirements, achieving the best possible economic and environmental efficiency. This also contributes to reducing CO2 emissions and improving the carbon footprint.

The return of the small 300-litre IBC, the only IBC of this size and capacity on the market, is also seamlessly managed through WERIT’s PACKONE system. The COMPACTline, with UN certification, is thus an intelligent alternative to drums and a particularly sustainable packaging solution alongside the already established IBC sizes of 600, 800, and 1,000 litres.