Furthermore, the unfilled IBCs should be secured by tamper evident closures. The transport of foodstuffs and their auxiliary materials such as flavours or colourings is becoming increasingly important. WERIT has developed the NUTRiline series for safe storage, easy transport and hygienic filling and emptying from the manufacturer to the user or small bottler in regional and global supply chains. Manufactured from virgin HDPE plastic, the WERIT containers are particularly strong, stable and meet the required specifications. Possible contamination is avoided through, a clean room production for IBC components, and innovative manufacturing process.

WERIT offers a wide range of NUTRiline IBCs. Customers can choose between 300, 600, 800 and 1000 liter IBCs on plastic pallets, with or without valve and from various sizes of filling neck openings. This IBC Food Family is now complemented by the NUTRiline aseptic with 600 and 1000 liters capacity. These comprise a combination of protective outer film, flexible inner film bag, stable tubular steel frame and an easy-care plastic pallet. This innovative, patented bulk packaging is supplied "ready-to-fill" and enables aseptic filling (and emptying) of sensitive, low to high viscosity liquids.

A powerful combination

NUTRiline aseptic IBCs combine the advantages of the robust WERIT IBC tubular steel frame on a high quality plastic pallet with the innovative aseptic flex bag system, resulting in a functional aseptic packaging solution.

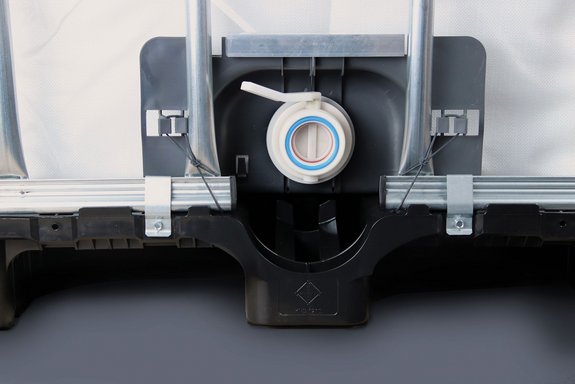

The outer, extra strong HDPE woven fabric provides protection against unwanted damage. The interior pouch is an Inliner with an outer layer of opaque metallized PET film, thermolaminated with PA to an inner layer of LDPE which protects the filling liquid from moisture, germs, oxygen and UV light. This preserves the freshness and efficiently extends the shelf life of the food.. The special film provides optimum flexibility to avoid "flex-cracks" (film breakage). An “Elpo” connection (the common filling systems in the food industry) is located on the upper side of the flexbag. Bottom fill is possible via the high-performance plastic valve with DN 50 milk pipe thread. It can be steam treated up to 125°C.

A separate, detachable handle lever on the valve prevents unintentional opening. It is also protected against tampering by a seal, which also has an indicator to show if sterilisation by radiation has taken place.

The NUTRiline aseptic AirAssist is equipped with air assistance for optimal emptying of highly viscous products. Through the AirAssist connection, air inflates a separate, integrated air cushion which enables the sterile and almost complete, emptying of highly viscous liquids. The NUTRiline aseptic has proven itself many times over and is "ready-to-fill" and "hands-free". It is an ideal system for the transport and processing of fruit and vegetable concentrates, fruit pulp and pastes, highly viscous foods such as liquid egg and dairy products as well as fragrances or flavours. This maintains the freshness of the products even when the evacuation is deliberately stopped part way through the emptying process.

The international return system via the PACKONE ticket closes an important, sustainable cycle, because the WERIT PACKONE ticket system allows the free return of all used and emptied IBCs, including IBCs of the NUTRiline family. The NUTRiline aseptic meets all the requirements for reconditioning due to its exchangeable components. The cooperation of WERIT with regional network partners guarantees short transport distances. After reconditioning, cleaning or replacement of various components, the IBC is returned to the economic cycle.

The WERIT NUTRiline Family offers customers safe, hygienic and sustainable solutions in differing sizes and equipment variants.