300 litre UN (max. density: 1.6)

300 litre IBC Container

COMPACTline

COMPACTline IBC

Versions & accessories

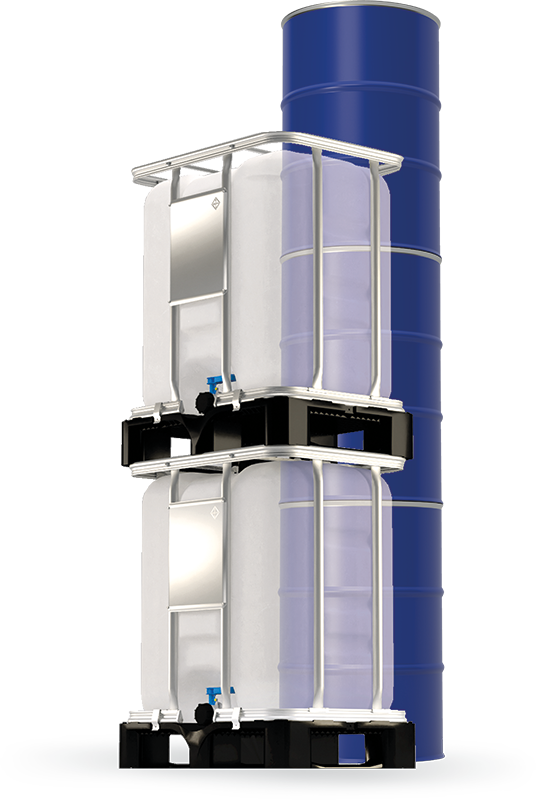

COMPACTline is the unique space saving IBC with 300 litre filling volume

- UN approved – Stable, stackable

- No markings necessary on the other side

- Optionally with tap S 56 x 4

- Optionally with integrated CDS withdrawal system

- Basic dimension corresponds with a half of a Euro pallet

Dimensions

The following dimensions are standardised IBCs for filling materials up to a density of 1.6 Rho

Volumes | length | width | height |

|---|---|---|---|

300 | 600 | 800 | 1000 |

Valves

We offer without valve or integrated valves.

Volumes | DN 50 mm | without |

|---|---|---|

300 |

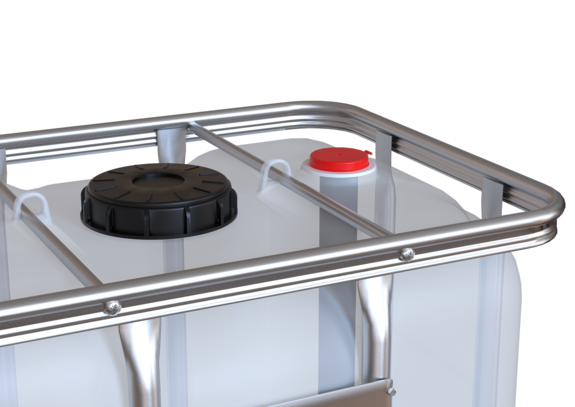

Lid

Volumes | DN 150 mm EPDM |

|---|---|

300 |

THE ADVANTAGES OF THE COMPACTLINE AT A GLANCE:

Due to its compact size, the unique 300 litre COMPACTline is ideal for confined spaces and working environments. It can be moved using a conventional pallet truck and fork lift. Thanks to its favourable size, it is usually ideal for liquids with short shelf life. Easy filling via the lid opening as well as withdrawal using the resealable drain valve make the COMPACTline to a simple functional packaging that is also excellent to completely empty.

Suitable for many filling media due to UN and food product approval. Multiple use due to reconditioning is given as a matter of course with the new COMPACTline.

- Small container for confined spaces or working environments, suitable for forklift transport

- Favourable size for liquids with short shelf life

- Simple withdrawal and outstanding residual emptying

- Multiple usage – Reconditioning possible

- Load securing: no extra costs due to wrapping, attaching, edge protection or padding material

- 2 safely stacked COMPACTline IBCs are equivalent to the volume of 3 drums

The Compact Alternative to Plastic Drums – also available with CDS Extraction System for AdBlue®

UN-certified and ideal for filling goods with short shelf life as well as for customers with low volume requirements.

MORE THAN A PRODUCT …

the solution for your industry

The economical provision and storage as well as the safe transportation of products are a fundamental link in the logistics chain of many industry segments. However, every industry also have their own individual specifications. The applications of the COMPACTline therefore fulfil cross-industry core requirements as well as specific needs.

The COMPACTline is an economical, sustainable and safe packaging solution for liquid media.

FAQ

Frequently Asked Questions

The 300 litre IBC container is the smallest and most compact version in our range. Those who opt for this product benefit from the ability to stack two units on a standard Euro pallet. This is thanks to its precisely coordinated dimensions of 600 x 800 mm, which equates to half the size of a Euro pallet (1,200 x 800 mm). These dimensions are standardised, as is also the case with larger models.

The next size up is no longer part of the COMPACTline and has a capacity of 600 litres. This model is available with integrated UV protection, UN approval or food-grade suitability. The 600 litre IBC and the 800 Euro variant are based on the Euro pallet footprint, while the standard 800 litre and 1,000 litre containers are designed for an industrial pallet size of 1,200 x 1,000 mm – also known as a block pallet.

300 litre IBC containers stand out thanks to their compact size. Whether a container is frost-resistant depends largely on the contents. The HDPE plastic used is not a limiting factor here. "HD" stands for high density, and the containers are made of high-quality polyethylene. The inner container typically withstands sub-zero temperatures with ease – provided it is empty.

When filled, the resistance to frost depends on the specific liquid. In some cases, antifreeze must be added, although this is not permissible in food applications. Freezing poses a risk of cracks or even complete container failure. As a solution, thermal covers or a container heater are recommended. Alternatively, a heated storage space can also be used.

One of the key advantages of 300 litre IBC containers is their ease of handling. All containers and tanks are stable and stackable. This allows for efficient use of space, especially as they fit onto half Euro pallets and can be grouped onto larger pallet units.

The volume of two 300 litre IBCs is equivalent to that of three barrels, yet due to their design, they require significantly less space.