WERIT gets you mobile

Mobility is the key word in the automobile and supplier industry. Products have to be transported from A to B quickly and safely. Particularly in times of ever shorter product life cycles, smaller batch sizes and rapid development times in the automotive industry, transport and storage solutions are in demand which offer the greatest possible flexibility and real module character.

Pallets and containers for electrostatically endangered components

WERIT transports all of these attributes in it world of products. This is how the innovative plastic pallet H1-L series originated, for example, according to this guiding principle. It was developed especially for the automotive industry and their suppliers. Being a conductive and antistatic plastic pallet, it protects the electrostatically endangered components against being charged.

The range of products is supplemented by the reusable transport packagings such as the Euro standard stacking boxes ESD , which are also made from electrostatically conductive plastic. The design and material prevent a potential electrostatic discharge. They are suitable for manual handling, but also for automatic conveying technology. Plastic pallets and plastic containers are break-proof, dimensionally stable and durable, as well as cold and heat-resistant and recyclable to 100 %.

Intermediate Bulk Containers for liquids

Being an expert for IBCs, WERIT is a sought-after partner of the automobile industry. With many production lines and four different sizes of the Intermediate Bulk Container, the company covers the needs in the area liquid storage and transport. The WERIT IBC are available with 300, 600, 800 and 1000 litre capacities. The range of products also offers various equipment versions for diverse areas of application and filling materials, e.g. for AdBlue® . Special IBCs with UN approval are even suitable for hazardous goods and flammable substances such as petroleum.

The handling and use of hazardous substances and flammable substances is a part of everyday work, especially in the automotive industry. It is good when you can rely on these also being packaged safely. With the IBC TOPline , POLYex and BLUELine , we have a range of products especially tailoured to these requirements. Convince yourself of the WERIT quality today.

IBC valve – You cant get any tighter

In addition to the IBCs, at WERIT you will also find comprehensive accessories in order to guarantee use in every industrial environment. Our customers put emphasis in safety and reliability, in particular when handling hazardous substances. Problems with the integrated valve may lead to unfavourable colouration and material loss, and toxic may be generated which could serious affect the health of employees. To prevent this, our development department has designed valves that belong to the most tightest on the market, even after being used several times. This makes sure that the smallest droplet is not lost, even under the hardest conditions.

Reconditioning - Environmental protection, really easy

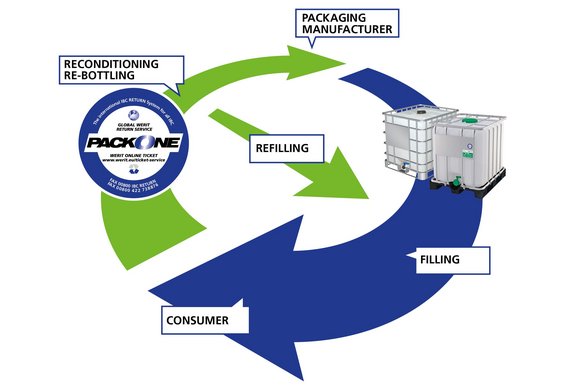

WERIT focuses on reconditioning. Under this, we understand returning our IBCs back to the resources circuit ( returnable system via the PACKONE Ticket service ). Confirmation that we are on the right track with this is reflected in the high demand in our RECOline programme.

Containers and pallets from WERIT are also 100% recyclable. Our plastic pallet H1-R or the product family of the IKP plastic pallets are, for example, manufactured from single-origin HDPE reclaim. As an ecological production and packaging is not only decisive for their customers, our partners also place great value in sustainable operations. Being a manufacturer of plastic packagings, we want to be a role model here. For this reason, we produce with low CO2emissions, promote recycling and protect the environment by the resource-conserving manufacturing of all of our products.